Improvement How can manufacturing companies solve high-cost waste through CNC turning

Introduction

The manufacturing sector, particularly in aerospace and medical device fields, frequently contends with significant waste during high-precision component production. Scrap rates can reach up to 20%, leading to escalated costs and project delays. The core issue lies in traditional machining methods’ reliance on manual operations, which are prone to human error, struggle with complex geometries, and lack standardized processes.

Introducing CNC turning technology, which utilizes digital control to achieve micron-level precision and incorporates intelligent optimization to minimize material waste, presents a transformative solution. The following analysis will delve into how CNC turning is becoming a cornerstone of manufacturing transformation.

Why can adopting CNC technology reduce waste by up to 30% in the Manufacturing Industry?

Waste is a critical cost driver in the Manufacturing Industry. Traditional turning methods, dependent on operator skill, result in inconsistent scrap rates due to variability and fatigue . These methods lack the repeatability and process control necessary for modern efficiency targets.

The Digital Advantage: From Artisan Skill to Automated Precision

The core of waste reduction lies in transitioning from manual control to digital automation. The CNC turning process is governed by pre-programmed instructions, ensuring that once a part design is validated, it can be reproduced identically thousands of times, eliminating quality fluctuations between operators or production batches . This repeatability is fundamental to reducing scrap.

Real-Time Monitoring and Adaptive Control

Advanced CNC turning centers are equipped with sensors that provide real-time feedback on tool wear and cutting conditions. This allows for immediate compensatory adjustments, preventing the production of out-of-tolerance parts before they become scrap . Furthermore, intelligent software optimizes tool paths and cutting parameters to maximize material usage from the raw billet, significantly reducing waste compared to manual nesting .

A Case in Point: Automotive Industry Success

For instance, in the automotive sector, producing transmission components like gear shafts with traditional methods often leads to high scrap rates. By switching to precision CNC turning services, manufacturers can achieve consistent micron-level accuracy. This digital process control has been shown to increase first-pass yield to over 99.5%, making production costs and timelines highly predictable and drastically reducing waste .

Data-Driven Consistency and Predictability

The digital nature of CNC turning provides comprehensive data on every aspect of production. This data enables continuous process improvement, further driving down waste over time. The ability to predict tool life and schedule maintenance prevents unexpected failures that lead to scrapped parts, ensuring a smooth, efficient, and low-waste operation .

How does CNC turning meet the micron-level precision demands of medical devices?

Medical devices, such as surgical instruments and implants, have exceptionally stringent requirements for biocompatibility, dimensional accuracy, and surface finish. Any micron-level deviation can compromise device functionality or patient safety. The trend towards Healthcare AI Solutions integrates with high-precision manufacturing to create next-generation smart medical devices.

CNC turning is uniquely positioned to meet these challenges. It enables the production of precision CNC turned parts with tolerances as tight as ±0.005 mm and superior surface finishes . For example, minimally invasive surgical tools require surface roughness values as low as Ra 0.4μm to ensure smooth operation and ease of sterilization . The process achieves this through high-rigidity machines, specialized tooling, and constant temperature control, ensuring that every precision CNC turned parts batch meets the exacting standards of the medical industry without deviation .

Which certifications ensure the reliability and consistency of CNC turned parts?

International certifications are the bedrock of quality assurance for a precision turned parts manufacturer. These certifications outline a comprehensive framework for quality management from design and procurement to production and final inspection, ensuring part reliability and consistency.

Certifications such as ISO 9001 (Quality Management), IATF 16949 (Automotive), AS9100D (Aerospace), and ISO 14001 (Environmental Management) provide this assurance . They mandate rigorous procedures for every step, including material certification, process validation, and comprehensive inspection using tools like Coordinate Measuring Machines (CMMs) . A manufacturer like JS Precision, which holds multiple such certifications, demonstrates a commitment to standardized, controlled production. This systemic approach minimizes the risk of human error and batch-to-batch variation, providing clients in high-stakes industries with critical confidence in part quality and supply chain security .

How does CNC turning tackle the challenges of titanium alloy processing in aerospace?

Titanium alloys are favored in aerospace for their high strength-to-weight ratio and excellent corrosion resistance. However, these same properties make precision CNC turning titanium notoriously difficult. The material’s low thermal conductivity leads to heat buildup at the cutting zone, while its high strength accelerates tool wear and can cause work hardening and elastic deformation of the part during machining .

Addressing these challenges requires a specialized approach. Strategies include using high-pressure coolant systems directed precisely at the cutting interface to manage heat . Selecting cutting parameters with lower speeds and appropriate feed rates, along with tools like ultra-fine grain carbide designed for titanium, mitigates work hardening and tool wear . Furthermore, the integration of automation trends, as seen in Practical Robotics, helps maintain a stable machining environment by minimizing human intervention. For complex components like satellite parts, leveraging advanced Precision CNC turning services is often essential to overcome these hurdles and meet the stringent standards of the aerospace industry .

How is the CNC turning process optimized for low cost and high efficiency?

Achieving cost-effective CNC precision turning requires holistic optimization of the entire manufacturing workflow, not just the machine runtime. This involves intelligent planning and execution at every stage to maximize efficiency in the Manufacturing Industry.

Intelligent Pre-Production Planning

Optimization begins before any metal is cut. Using CAM software, technicians simulate and optimize the CNC turning process to minimize non-cutting time (air cutting) and prevent collisions . A thorough Design for Manufacturability (DFM) review identifies potential production issues early, allowing for design adjustments that simplify machining and reduce costs .

Lean Manufacturing Execution on the Shop Floor

The machining process itself is structured to be lean and efficient.

Strategic Machining Stages

The process is typically divided into stages: roughing, semi-finishing, and finishing. Roughing uses aggressive parameters to quickly remove bulk material. Semi-finishing ensures a uniform allowance for the final cut. Finishing, performed with fresh tools and precise parameters, achieves the final dimensions and surface quality. This staged approach protects precision tools and ensures optimal results .

Tooling and Time Management

Effective tool management, including pre-set tooling off-machine, drastically reduces setup time. Monitoring tool life and replacing tools proactively prevents failures that cause scrap and downtime . For large-volume orders, integrating CNC turning into automated production lines with robotics represents the ultimate step in minimizing unit cost .

Continuous Monitoring and Quality Assurance

In-process inspection with probes allows for real-time measurement of key dimensions. The system can automatically compensate for tool wear, ensuring consistent quality throughout a production run and avoiding the cost of scrapped parts . This closed-loop process is a hallmark of an optimized CNC turning operation, leading to higher efficiency and lower overall costs.

Conclusion

In summary, CNC turning technology effectively addresses the long-standing issues of waste and inconsistency in manufacturing through its digital control, micron-level precision, and standardized processes. It provides reliable, high-quality part support for demanding sectors such as aerospace and medical devices. For projects facing precision, efficiency, or cost-control challenges, exploring custom CNC turning solutions is a critical step forward.

To optimize your production workflow, it is recommended to consult with a specialist for a free consultation and an immediate quote on custom CNC turning solutions.

Author Biography

The author is a senior manufacturing industry analyst with a decade of experience, specializing in research on precision technology and automation trends.

FAQs

Q1: Is CNC turning technology suitable for small-batch production?

A: Yes, CNC turning is highly suitable for small batches. Its digital programming allows for quick adaptation to different designs without the need for expensive custom tooling, making it ideal for prototyping and low-volume orders.

Q2: How do you select the appropriate material for CNC turning?

A: Material selection depends on the application’s requirements. For instance, aerospace commonly uses titanium alloys for strength and lightness, while the medical field often prefers stainless steel for its biocompatibility. Consulting with an expert who can recommend materials based on performance parameters is the best approach.

Q3: What is the typical lead time for CNC turned parts?

A: Standard lead times are typically 1-3 business days for common complexities, depending on order quantity and material availability. Expedited options are often available to shorten this timeframe to just a few days.

Q4: Can CNC turning handle complex geometric shapes?

A: Absolutely. Modern multi-axis CNC turning centers can complete turning, milling, drilling, and threading operations in a single setup, enabling the production of complex contours, eccentric shapes, and micro-features with micron-level precision.

Q5: Which industries benefit most from CNC turning technology?

A: Industries with the highest requirements for part precision and consistency benefit the most. This includes precision manufacturing, automotive (especially new energy vehicle systems), aerospace, medical devices, and high-end electronics.

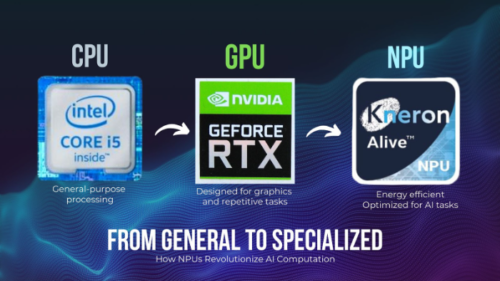

CES 2026 Signals the Shift From GPUs to NPUs: Why Kneron Fits the Inference-First Future of AI

CES 2026 will likely be remembered less for a single headline-grabbing product and more for a quiet recalibration of how the AI industry defines progress. The dominant signal this year wasn’t about who trained the largest model or shipped the fastest GPU. It was about where AI actually works and whether it can survive outside controlled environments.

Across keynotes, panels, and private conversations, a consistent pattern emerged: AI is moving out of the lab and the cloud and into the physical world. That transition favors a very different class of companies; those designed for deployment, reliability, and constraint, rather than scale-for-scale’s-sake performance.

Intelligence Is Moving Closer to the World

Both Lisa Su and Jensen Huang framed the next phase of AI around physical interaction: robots, autonomous machines, industrial systems, and real-time decision-making. These environments impose hard requirements: low latency, predictable behavior, energy efficiency, and resilience that don’t map cleanly onto cloud-centric architectures.

The implication is subtle but decisive. Training remains centralized, but intelligence becomes distributed. AI must operate in cars, factories, hospitals, and embedded devices often disconnected, often power-constrained, and always exposed to real-world variability. Once AI leaves the cloud, the definition of “performance” changes.

And with it, so does the competitive landscape.

Why Inference Has Become Strategic

For much of the last decade, inference was treated as an optimization problem; a downstream concern once training dominance was established. CES 2026 inverted that logic. Inference is now the bottleneck for scale, cost, and real-world adoption.

This is where inference-first architectures become structurally advantaged. Companies like Kneron are not retrofitting data-center hardware for edge use; they are designed around the constraints that real-world AI imposes from the start. Low power consumption, deterministic latency, security, and long deployment lifecycles are not secondary features but rather, foundational design choices.

As AI expands into regulated, safety-critical, and industrial settings, these constraints stop being edge cases and start becoming requirements. Inference is no longer about throughput alone; it’s about whether AI can be trusted to operate continuously, locally, and predictably.

From Chips to Deployable Systems

Another recurring theme at CES was the industry’s shift from selling components to delivering systems. A chip by itself does not deploy AI. Real-world adoption requires a secure operating system, optimized runtimes, orchestration tools, and integration with sensors and existing infrastructure.

This is where Kneron’s positioning becomes clearer. Rather than remaining a standalone silicon vendor, the company has evolved toward a system-level approach providing a tightly integrated stack that helps customers move from proof-of-concept to production without rebuilding everything around the chip.

That trajectory mirrors a broader industry insight articulated by Advanced Micro Devices: as markets fragment and use cases multiply, ecosystems outperform monolithic architectures. The companies that win are not those with the loudest benchmarks, but those that make deployment repeatable.

Taiwan’s Role Is Structural, Not Accidental

CES 2026 also reinforced the renewed importance of Taiwan, not merely as a manufacturing hub, but as a convergence point for execution-focused AI. Hardware-centric intelligence demands tight feedback loops between chip design, software integration, and mass production.

Companies embedded in this ecosystem can iterate faster and reduce deployment risk in ways cloud-first players often cannot. When AI must ship as a product rather than a demo, proximity to execution becomes a competitive advantage, not a logistical detail.

A Quieter Kind of Leadership

What CES 2026 ultimately suggested is that the next generation of AI leaders may not dominate headlines in the way past giants did. Their influence will show up elsewhere: in how many systems ship, how reliably they operate, and how easily customers can scale from pilot to production.

Kneron occupies that quiet middle layer between models and markets, the layer where AI stops being theoretical and starts functioning as infrastructure. As the industry shifts from asking how powerful can AI become to how widely can AI be deployed, that position looks less peripheral and more essential.

CES 2026 didn’t declare a winner. It clarified the rules. And under those rules, inference-first, system-level companies are no longer supporting actors they are foundational to what AI becomes next.

6 Best Employer of Record (EOR) Companies Powering Global Hiring in 2026

Global talent is everywhere. Legal entities are not.

Companies expanding internationally face a choice: spend months establishing legal entities in each country or use an Employer of Record to hire immediately. EOR providers become the legal employer for your international team members, managing contracts, payroll, benefits, and compliance while you run the business.

The difference between EOR providers shows up in how they handle compliance, where they operate, and whether they own their infrastructure or rely on partners. Below are the 6 Best EOR provider companies that make global hiring operationally viable.

1. Remote

Coverage: 90+ countries

Infrastructure: Owned legal entities

Remote’s EOR service allows companies to hire workers in more than 90 countries without establishing local legal entities. The platform manages everything from employment contracts and statutory benefits to payroll, tax compliance, and local filings, all under its own legal entities. Because Remote owns the legal entities where it operates, compliance updates and wage rule changes are implemented directly through relationships with local authorities rather than through intermediaries. This approach reduces risk and delays caused by partner coordination. Remote also consolidates employment, payroll, benefits administration, and HR tools into one system, reducing administrative overhead and the potential for data inconsistencies.

Remote’s infrastructure is consistent across markets, meaning companies do not need to adapt to different systems or partners when they expand into new countries.

Why it works: It combines owned compliance infrastructure with unified workforce administration, giving teams dependable and predictable global hiring operations.

Best suited for:

Companies prioritizing compliance certainty and long term scalability in their international hiring infrastructure.

2. Deel

Coverage: 150+ countries

Infrastructure: Mix of owned entities and partnerships

Deel enables hiring in more than 150 countries by combining its own legal entities with local partnerships where necessary. Its EOR services include employment contract generation, payroll management, statutory benefits, and compliance monitoring. Deel goes beyond basic EOR by integrating global payroll for contractors and full-time employees in the same platform, along with tools for workforce analytics and reporting. These analytics help HR and finance teams understand labor costs, headcount distribution, and compliance obligations across regions. Deel also integrates with existing HR and financial systems, reducing the need for manual data transfers.

Because Deel unifies multiple workforce types in one system, it reduces administrative complexity for companies with mixed employee types.

Why it works: Extensive country coverage and broad tool integration support flexible workforce strategies and clearer global workforce insights.

Best suited for:

Organizations needing broad coverage and integrated tools for managing mixed workforce models globally.

3. Oyster

Coverage: 120+ countries

Infrastructure: Partnership model

Oyster’s EOR services span more than 120 countries, built on a network of partners and compliance teams that manage employment contracts, local statutory compliance, payroll, and benefits administration. Oyster places emphasis on employee experience, offering tools for compensation benchmarking, equity management, expense handling, and benefits access tailored to each market. The platform also provides regularly updated guidance on local hiring requirements, onboarding processes, and compliance best practices to support HR teams entering new markets.

Oyster’s focus on clarity and simplicity helps organizations reduce the friction typically associated with cross-border hiring.

Why it works: It blends essential EOR functions with market compensation data and employee-centered tools, making global hiring smoother for both HR teams and employees.

Best suited for:

Companies where employee experience and integrated HR functionality are priorities alongside compliance management.

4. Papaya Global

Coverage: 160+ countries

Infrastructure: Partner network model

Coverage: 160+ countries

Infrastructure: Certified partner network with compliance expertise

Papaya Global supports employment and payroll in over 160 countries through a network of certified local partners and its compliance infrastructure. The platform centralizes payroll processing, statutory benefit administration, workforce payments, and compliance monitoring for international teams. Papaya also offers reporting and analytics designed for finance and HR teams, giving visibility into workforce costs, compliance checkpoints, and payment timelines. This structure is particularly helpful for enterprises operating in multiple jurisdictions with complex payroll and reporting needs.

Papaya’s combination of local compliance expertise and centralized workforce insights supports large-scale hiring and governance.

Why it works: It provides broad global reach while giving finance teams comprehensive reporting and control over workforce operations.

Best suited for:

Organizations with sophisticated payroll needs and requirements for detailed workforce analytics across many countries.

5. Multiplier

Coverage: 150+ countries

Infrastructure: Partnership model

Multiplier offers EOR services in more than 150 countries, handling employment contracts, payroll, statutory benefits, and compliance monitoring through a blend of local partners and legal infrastructure. The platform emphasizes speed and simplicity, with onboarding workflows designed to minimize time to hire. Multiplier also integrates holiday and time off management, equipment tracking, and expense handling, so teams have a single place to manage typical workforce administration tasks.

While its infrastructure relies on partner networks in many regions, Multiplier’s platform interface and onboarding experience are designed to reduce administrative burden.

Why it works: Quick onboarding and straightforward operational workflows shorten the time between hiring decisions and workforce deployment.

Best suited for:

Companies that value speed and simplicity in their international hiring processes.

6. Rippling

Coverage: 80+ countries

Infrastructure: Owned entities where available

Rippling’s Employer of Record service allows companies to hire and pay employees in more than 80 countries where the company does not already have a legal entity. According to Rippling’s official site, the service manages local employment agreements and payroll processing, handles required tax compliance, and sets up benefits for employees automatically through the platform. Rippling brings these employment functions together with its HR and payroll systems, meaning teams do not need separate tools for hiring, paying, and maintaining workforce records.

The platform also guides companies through compliance requirements specific to each country by collecting necessary information during the hiring process, helping reduce risk and manual work for HR and finance teams. Rippling’s central system gives visibility into employee data, pay runs, and compliance status in one place instead of scattered across multiple services.

Why it works: It gives companies a single system for hiring, paying, and managing international employees while helping ensure that local laws are followed.

Best suited for:

Companies wanting EOR capabilities as part of a comprehensive, unified workforce operations platform.

What Matters When Choosing an EOR Provider

Geographic coverage determines where you can hire, but infrastructure determines how well it works. Providers with owned entities respond faster to regulatory changes and offer clearer accountability. Partner based models provide broader reach but may slow compliance due to extra coordination.

Consider your expansion plans and risk tolerance. Companies with long term presence in certain markets benefit from strong local infrastructure. Teams exploring multiple countries quickly may prioritize wider coverage first. Integration with payroll, benefits, and HR systems reduces administrative work and improves accuracy. Standalone EOR solutions offer flexibility but require more coordination.

These providers offer different approaches to the same challenge: making international employment legal and manageable. The right choice depends on which model fits your growth strategy rather than feature counts alone.

Practical Application Scenarios of an Advanced AI Image Generation Model

Artificial intelligence has transformed the way visuals are created, enabling individuals and businesses to produce high-quality images without traditional design limitations. At the heart of this shift is Nano Banana, an AI-powered image generation model built exclusively for creating visuals through Text-to-Image and Image-to-Image processes. By focusing solely on image creation, this model delivers consistent, high-quality results across a wide range of creative and professional use cases.

Creative Design and Concept Visualization

One of the most common application scenarios for AI-generated images is early-stage concept development. Designers, illustrators, and artists can turn written descriptions into visual drafts within seconds. This allows creative professionals to experiment with styles, color palettes, lighting, and composition before committing to a final design. Image-to-Image generation further enhances this workflow by enabling users to refine existing visuals while preserving their original structure.

Marketing and Branding Content

AI-generated imagery plays an increasingly important role in modern marketing. Brands can generate custom visuals for advertising campaigns, social media posts, blog illustrations, and landing pages without relying on stock photography. With Nano Banana, marketing teams can create consistent visuals that match brand identity while saving time and production costs. The ability to rapidly generate tailored images helps businesses stay agile in fast-moving digital environments.

E-commerce and Product Visualization

Product presentation is essential in e-commerce. AI image generation allows sellers to create lifestyle scenes, product mockups, and background variations without physical photo shoots. By using Image-to-Image generation, existing product photos can be enhanced, restyled, or adapted for different platforms. This approach improves visual appeal while maintaining accuracy and consistency across listings.

Education, Storytelling, and Content Creation

Educators, writers, and content creators can use AI-generated images to support storytelling and visual learning. From illustrating fictional scenes to visualizing historical or scientific concepts, AI images help audiences better understand and engage with content. These visuals can be generated quickly based on text prompts, making them ideal for presentations, articles, and educational materials.

Personal Creativity and Exploration

Beyond professional use, AI image generation also empowers personal creativity. Hobbyists can explore imaginative ideas, generate artwork for personal projects, or experiment with visual styles they may not have the skills to create manually. With Nano Banana, users are free to focus on imagination rather than technical complexity, turning ideas into visuals with ease.

Conclusion

As AI-driven creativity continues to evolve, image-focused models are becoming essential tools for both practical and artistic applications. By offering only Text-to-Image and Image-to-Image generation, Nano Banana remains dedicated to delivering powerful, flexible, and visually compelling results. Whether used for design, marketing, education, or personal expression, AI-generated images are reshaping how visuals are created and experienced.

How Brands Are Rethinking Social Media Growth in 2026

Social media growth strategies are evolving. Instead of chasing aggressive tactics or short-term viral results, brands, creators, and startups are shifting toward data-driven, sustainable approaches. In 2026, the focus is increasingly on long-term audience development, consistency, and performance insights rather than instant visibility.

The Evolution of Social Media Growth Tools

Modern marketing teams now rely on a combination of tools designed to improve efficiency and decision-making, including:

Content planning and scheduling

Performance and engagement analytics

Audience behavior analysis

Campaign testing and optimization

These tools allow businesses to move beyond manual trial and error and adopt structured workflows that align with platform policies and long-term growth goals.

Why Centralized Social Media Management Matters

Managing multiple social platforms independently often leads to challenges such as:

Inconsistent posting schedules

Limited visibility into performance data

Inefficient use of marketing budgets

To address this, many teams are turning to centralized social media management solutions that enable them to monitor engagement, test campaigns with controlled budgets, and identify which content formats perform best across platforms.

Platforms Supporting Responsible Social Media Growth

As the industry shifts toward responsible growth, several platforms have emerged to support creators, brands, and agencies with structured engagement solutions and analytics-focused dashboards.

One example is BuyTheFans, which positions itself as a social media growth and engagement management platform designed for teams that value organization, reporting, and scalable workflows. Rather than promising instant results, platforms in this category are increasingly used as supporting tools within broader digital marketing strategies.

Data Transparency and Greater User Control

Transparency has become a key requirement in modern social media marketing. Brands now expect tools that provide:

Clear and accessible reporting

Predictable campaign delivery

User-controlled growth and engagement settings

This level of control allows marketers to make informed decisions based on real data rather than assumptions or short-term metrics.

The Future of Social Media Marketing

Looking ahead, successful brands will be those that:

Combine high-quality content with performance insights

Use tools that support gradual, controlled audience growth

Avoid practices that compromise brand trust or platform compliance

Social media success is no longer defined by follower counts alone. In 2026, sustainable growth, audience relevance, and measurable impact are the key factors driving effective social media marketing.

Zero Knowledge Proof Draws Trader Interest While AVAX & DOGE Remain Under Pressure

Recent trading sessions show strong movement across the crypto market as participants respond to shifting signals and changing confidence. Current Dogecoin price prediction data points to ongoing caution, as weak buying interest and fragile sentiment continue to weigh on the memecoin. Market watchers are closely tracking key levels to judge whether selling pressure will persist or if balance can slowly return.

At the same time, Avalanche price behavior reflects a comparable challenge. Short-term rebound efforts keep running into resistance, while mixed indicators signal uncertainty for those following the trend. This has kept many traders alert and selective as conditions remain uneven.

While these well-known assets struggle to regain traction, attention is turning toward projects like Zero Knowledge Proof (ZKP). Its strict anti-whale limit, structured presale auction model, projected ROI, and practical AI-focused use cases have helped it stand out. Growing participation from informed traders has placed it firmly among the top crypto gainers being tracked this year.

Dogecoin Price Prediction Signals Ongoing Weakness

Recent price behavior keeps Dogecoin under pressure as trades remain locked within a descending channel. Because of this structure, the Dogecoin price prediction outlook stays guarded. Sellers continue to guide momentum while low liquidity limits recovery strength. Short bounces lose steam near key averages around $0.126, showing that confidence remains limited. Broader sentiment also stays delicate, as uneven recoveries in Bitcoin and Ethereum reduce interest in higher-risk meme assets.

Indicator readings reinforce this cautious tone. The Dogecoin price prediction now relies heavily on support holding near $0.120, an area tested several times. Each test weakens support strength over time. Resistance is seen near $0.142, where bearish trend signals remain active.

ETF figures offer little relief, with assets staying close to $5 million. Without stronger volume or a wider shift in sentiment, near-term movement may remain flat or tilt lower. Short-term momentum continues to appear soft, keeping Dogecoin out of the list of top crypto gainers for now.

Avalanche Price Struggles to Build Recovery Above Key Levels

Current Avalanche trading holds close to $13, showing limited follow-through after recent swings. Avalanche price action stays slightly above the 20-day average near $12.62 but remains capped below the 50-day level at $13.83 and far under the 200-day level around $20.89. This layout hints at short-term balance but continued pressure across the broader trend. Buyers are present, yet selling interest still limits upside attempts. Attention remains fixed on whether the $12.40 support area can stay intact during pullbacks.

Wider updates add background but do not remove uncertainty. Avalanche price responses to treasury planning and ETF filing developments have been muted, leaving momentum mixed. Daily tools continue to lean negative, with MACD and ADX readings suggesting sellers still hold control. Many analysts now expect range-bound action between $12.40 and $13.50. A clear move above resistance could reduce pressure, while a drop below support may extend losses and keep Avalanche away from the top crypto gainers list.

Zero Knowledge Proof (ZKP) Gains Focus With $50K Anti-Whale Rule

Growing attention around the Zero Knowledge Proof (ZKP) presale auction is emerging as several established assets fail to regain strength. As traders search for early-stage opportunities in 2026, many are choosing to engage with ZKP during its active presale auction rather than wait for later stages.

A key feature drawing interest is the firm rule that caps daily participation at $50,000 per wallet. This rule helps ensure the presale auction remains balanced by preventing large wallets from influencing price behavior. Because of this setup, participants of different sizes feel more comfortable joining under the same conditions.

The anti-whale system shapes market behavior in a clear way. With equal limits applied to everyone, supply cannot be controlled by a single participant. Price movement reflects true demand instead of sudden large entries. This reduces sharp swings and builds trust from the earliest stage. Many traders favor systems where rules are consistent, and that fairness supports steady interest over time.

Another layer of balance comes from the presale auction design itself. Each day features a unique price based only on that day’s activity. Higher demand naturally leads to higher pricing, while lower participation keeps prices steady. No manual adjustments are involved, as the process is fully driven by formulas. Participants receive an averaged entry price tied to overall activity, removing hidden changes and limiting manipulation. This level of openness is still uncommon across many early-stage launches.

Beyond the presale auction, Zero Knowledge Proof (ZKP) is advancing real-world functionality. The project is developing a privacy-focused infrastructure aimed at artificial intelligence use. Its network enables secure data sharing and computation, allowing collaboration without exposing sensitive information. As AI adoption expands, this approach fits well with future requirements. Because of fairness, practical design, and early visibility, many now rank it among the top crypto gainers to watch. With infrastructure live, the network active, and proof pods already shipping, awareness is gradually building. Some analysts continue to reference ROI as a long-term possibility as progress remains visible on-chain.

Final Thoughts

As the year moves forward, mixed signals continue to shape the crypto market direction. Dogecoin price prediction trends remain cautious, with weak demand and limited liquidity keeping pressure in place. Meanwhile, Avalanche price action faces ongoing resistance, as recovery efforts struggle against broader negative momentum.

With volatility affecting these names, many traders are shifting attention toward the live Zero Knowledge Proof (ZKP) presale auction. Its $50K anti-whale rule, transparent structure, active network, and AI-driven use cases set it apart from many alternatives. This blend of utility and clarity is why Zero Knowledge Proof (ZKP) is increasingly viewed as one of the potential top crypto gainers for 2026, with analysts continuing to discuss long-term upside reaching ROI.

Explore Zero Knowledge Proof:

Auction: https://auction.zkp.com/

Website: https://zkp.com/

Telegram: https://t.me/ZKPofficial

Disclaimer:

This article is for informational purposes only and does not constitute financial advice. Cryptocurrency investments carry risk, including total loss of capital.

All market analysis and token data are for informational purposes only and do not constitute financial advice. Readers should conduct independent research and consult licensed advisors before investing.

Crypto Press Release Distribution by BTCPressWire.com

The Micro-Soldering Difference: Why Your Repair Shop Needs Logic Board Expertise

Introduction: The “Unfixable” Verdict

There is a specific, sinking feeling that every smartphone owner fears. It happens when you walk into a bright, polished manufacturer store or a quick-fix kiosk at the mall. You hand over your device—which contains photos of your children, messages from lost loved ones, and years of contacts—hoping for a simple fix.

The technician runs a 3-minute diagnostic, looks up, and delivers the bad news: “I’m sorry. It’s a logic board failure. It can’t be fixed. You’ll have to buy a new device, and unfortunately, your data is gone.”

For 90% of the world, that is the end of the story. The phone goes into a drawer or a landfill, and the memories are lost. But for the 10% who know about the hidden world of board-level repair, that verdict is just a first opinion.

The reality is that manufacturers and basic repair shops are often “part swappers.” They are excellent at uncrewing a screen and screwing in a new one. But when the damage goes deeper—into the microscopic city of circuits that powers the device—they are out of their depth. As a team dedicated to expert phone repair New Haven, we are here to tell you that “dead” is rarely truly dead.

In this extensive guide, we are going to take you behind the microscope. We will explain exactly what micro-soldering is, why “unfixable” phones are often just one tiny broken component away from working, and how true experts save data when everyone else says it’s impossible.

Section 1: Anatomy of a Logic Board

Understanding the Brain of Your Device

To understand why standard repair shops fail where micro-soldering succeeds, you have to understand the complexity of the device in your pocket.

Your phone isn’t just a screen and a battery. At its heart lies the Logic Board (or Motherboard). This green or blue circuit board is a marvel of modern engineering. It is a High-Density Interconnect (HDI) board, meaning it has multiple layers—sometimes up to 10 or 12 layers of copper wiring sandwiched inside the fiberglass board itself.

On the surface of this board are thousands of components:

- Resistors: Tiny specks that regulate the flow of current.

- Capacitors: “Buckets” of energy that smooth out electricity.

- ICs (Integrated Circuits): The black chips that handle specific tasks like audio, touch, charging, and processing.

- Filters: Fuses that protect the board from power surges.

Many of these components are smaller than a grain of sand (the 01005 package size is literally dust-sized to the naked eye). When you drop your phone, bend it, or get it wet, you aren’t just cracking the glass; you are subjecting this microscopic city to an earthquake. A single cracked solder joint under a chip, or one knocked-off capacitor, can stop the entire phone from turning on.

A standard repair shop cannot see this damage. They swap the battery, and if that doesn’t work, they give up. A micro-soldering technician, however, sees the board differently.

Section 2: The Diagnostic Detective Work

How We Find the Needle in the Haystack

You might wonder, how do you find one broken component among thousands? This is where the true expertise comes in. It is not guessing; it is physics and electrical engineering.

- The Power Meter (The Heartbeat Monitor) Before we even open the phone, we plug it into a specialized USB power meter (Amperimeter). This tells us how much current the phone is drawing.

- 0.00 Amps: The “circuit is open.” Usually a dead battery or a broken connection.

- 0.08 Amps (Stuck): The phone is trying to boot but getting stuck at the RAM check.

- High Current (Shutdown): There is a “Short Circuit.”

- Finding the Short (Thermal Imaging) A “short circuit” is the most common reason a phone won’t turn on. Imagine water pipes in your house. If a pipe bursts (a short), all the water pressure drops, and no water reaches the shower (the CPU). In a phone, if a capacitor breaks internally, it dumps all the power to the ground. The phone protects itself by shutting off all power.

To find the bad capacitor, we inject voltage into the board and use a Thermal Camera. The damaged component will glow bright orange or red on the camera screen because it is heating up as it dumps electricity. It’s like using night-vision goggles to spot a fire in a forest.

- Diode Mode Readings We use a multimeter to measure the resistance of specific lines on the board. We compare these numbers to the official schematics (blueprints) of the phone. If a line that is supposed to read “0.450” reads “0.000,” we know exactly which pathway is broken.

This level of diagnostic capability is what separates a mall kiosk from a trueiPhone repair New Haven laboratory. We don’t guess; we measure.

Section 3: The Tools of the Trade

It’s Not Just a Soldering Iron

You cannot do this work with a soldering iron from a hardware store. Those irons are too large and too hot; they would burn a hole right through a modern iPhone logic board. Micro-soldering requires a setup that looks more like a surgical theater than a repair bench.

- Stereo Microscope: We work under 10x to 45x magnification. The components we work on are invisible to the naked eye. We need to see the texture of the solder joints to ensure a perfect connection.

- Hot Air Rework Station: To remove a chip that has 100 pins underneath it, you can’t use an iron. We use a precise hot air gun that blows air at exactly 360°C to melt the solder underneath the chip without burning the plastic connectors nearby.

- Micro-Pencil Irons: Our soldering tips are filed down to 0.1mm—sharper than a needle. This allows us to work on a single component without touching the ones next to it.

- Jumper Wire: When a copper trace inside the board breaks (like a collapsed tunnel), we have to build a bridge over it. We use enameled copper wire that is thinner than a human hair to manually reconnect the circuit.

Section 4: Famous Flaws We Fix (The “Epidemics”)

Design Flaws vs. User Damage

Sometimes, you didn’t do anything wrong. Your phone just broke because of a weak point in the manufacturing design. We see these “epidemics” in waves.

The “Tristar” Problem (iPhone Charging Issue) This is the #1 issue we see. You plug your phone into a cheap gas station charger or a frayed cable. These cheap cables don’t regulate voltage well. They send a spike of electricity that fries a chip called “Tristar” (or Hydra in newer phones).

- Symptoms: The phone says it’s charging but the percentage drops; it won’t charge past 1%; or the battery drains rapidly.

- The Fix: We have to desolder the Tristar chip and replace it with a new one. A battery replacement will never fix this.

Audio IC (iPhone 7/7 Plus) This was a massive issue. The Audio IC chip was placed on a weak spot of the board. Over time, slight bending of the phone caused the connection pads under the chip to tear.

- Symptoms: Greyed-out speaker button, voice memos don’t work, boot looping (taking 5 minutes to turn on).

- The Fix: We remove the chip and run tiny micro-jumpers to reinforce the broken track, essentially “bolting” the electrical line down so it never breaks again.

HDMI Ports (PlayStation/Xbox) While not a phone, this is pure soldering. Kids trip over HDMI cables, ripping the port off the motherboard. You cannot glue this back. The old port must be removed with high heat (without melting the board), and a new heavy-duty port must be soldered into place with perfect precision.

Section 5: The Truth About Water Damage

Why Rice is a Myth and Cleaning is Science

If there is one thing we want you to take away from this blog, it is this: Do not put your wet phone in rice.

Rice is a placebo. It might absorb some moisture from the outside of the phone, but it does nothing for the water trapped inside. While the phone sits in rice for 2 days, the water inside is reacting with the battery’s electricity to create corrosion.

Corrosion is like rust on steroids. It eats through the copper pins and solder joints. It creates “green fuzz” (oxidation) that causes short circuits.

The Real Solution: Ultrasonic Cleaning When a water-damaged device comes to our shop, we don’t dry it; we clean it.

- We remove the logic board.

- We place it in an ultrasonic cleaner filled with a specialized chemical solution.

- The machine uses high-frequency sound waves to create microscopic bubbles that implode, blasting the corrosion out from under the chips.

- We then soak it in 99.9% isopropyl alcohol to displace the water.

- Finally, we use the microscope to inspect for eaten-away solder joints and rebuild them.

This process saves thousands of devices that rice would have let rot.

Section 6: Data Recovery – The Last Resort

When the Phone Doesn’t Matter, But the Photos Do

Sometimes, a phone is physically destroyed. Maybe it fell off a roof, was crushed by a car, or spent a week at the bottom of a lake. In these cases, the screen, the frame, and the battery are trash. But the data lives on the NAND Flash Chip.

However, modern security (especially on iPhones) means you cannot simply desolder the storage chip and put it onto another board or into a USB reader. The storage is encrypted and married to the CPU and the EEPROM (security chip). They are a “trio.”

The Board Swap / Transplant To recover data from a destroyed board, we have to perform a “transplant.” We carefully desolder the CPU, the NAND, and the EEPROM from the dead board. We then take a “donor” board (a working phone), remove its chips, and solder your chips onto that working board.

This is the neurosurgery of electronics repair. It requires incredibly steady hands and patience. If the CPU gets too hot during the transfer, the data is gone forever. But when it works, it is magical. We can power on the franken-phone, type in your passcode, and back up your life.

If you have been told your data is unrecoverable, you need to consult a phone repair New Haven specialist before you lose hope.

Section 7: Conclusion

We live in a throwaway culture. Manufacturers incentivize us to upgrade every year, and they design devices that are increasingly difficult to open. But the “right to repair” is about more than just saving money—it’s about ownership and sustainability.

Micro-soldering is the ultimate form of repair. It refuses to accept that a $1,000 device is trash just because a $2 capacitor failed. It keeps electronics out of landfills and keeps money in your pocket.

So, the next time your screen goes black or your device stops charging, don’t rush to the sales counter for an upgrade. Ask the question: “Does this shop do board-level repair?” If they don’t, you haven’t found the real problem yet.

Frequently Asked Questions (FAQs)

Q1: How long does a micro-soldering repair take compared to a screen repair? A1: A screen repair takes 20 minutes because it is a modular swap. Micro-soldering takes longer—usually 3 to 7 business days. This is because we need time to diagnose the schematic lines, perform the delicate soldering work, and then “stress test” the device to ensure the fix holds up under heat and usage.

Q2: Is it worth fixing an older phone with micro-soldering? A2: It depends on your goal. If you just want a working phone, sometimes an upgrade is cheaper for very old models. However, if you need the data (photos, notes, Authenticator apps) that wasn’t backed up, micro-soldering is priceless. It is often the only way to get that data back.

Q3: Can I learn micro-soldering myself? A3: You can, but the learning curve is steep. It requires a significant investment in tools (approx. $1,000+ for a decent starter setup) and hundreds of hours of practice on dead boards. One slip of the hand can knock off components that are critical for the phone’s function.

Q4: Will micro-soldering void my warranty? A4: Yes. Once a third-party technician melts solder on the motherboard, the manufacturer’s warranty is void. However, most people seeking this service are already out of warranty or have been told by the manufacturer that the device is ineligible for repair (e.g., due to liquid damage).

Disclaimer

The information provided in this blog post is for educational purposes only. Logic board repair involves high heat (350°C+), hazardous fumes, and delicate electrical components. It should never be attempted without professional training, ventilation, and proper equipment. We are not responsible for damage caused by amateur repair attempts.

Entrepreneur Matt Haycox On Why Failure Is A Requirement, Not A Flaw

Failure is still treated like a dirty word in entrepreneurship. Wins are amplified, losses are quietly buried and success is framed as something linear and controllable. But for entrepreneur and investor Matt Haycox, that story does more harm than good.

Haycox’s view is shaped by lived experience. Across more than two decades in business, he has built, scaled and lost companies in public view, navigating bankruptcies, legal pressure and rebuilds along the way. Rather than distancing himself from those moments, he argues they are central to understanding what entrepreneurship actually demands.

‘If you’ve never failed, you’ve probably never put yourself properly on the line,’ Haycox says. ‘Failure isn’t a flaw. It’s part of the job description.’

Why business failure is judged differently

In most areas of life, failure is treated as temporary. Exams can be retaken. Careers can pivot. Even personal setbacks are often framed as growth experiences. Business, Haycox believes, is judged by a harsher standard.

‘When a business collapses, people treat it like a moral failure,’ he says. ‘As if the person behind it is broken.’

That judgement ignores the reality of entrepreneurship. Building a business means making decisions with incomplete information, taking financial risk and being accountable for outcomes that are not fully controllable.

Research from the World Economic Forum has highlighted that entrepreneurial ecosystems with low tolerance for failure tend to discourage innovation and risk-taking. Where failure is stigmatised, founders delay decisions, hide problems and avoid bold moves.

‘If the penalty for failure is permanent,’ Haycox says, ‘people stop telling the truth.’

What failure actually removes

Haycox is clear that failure does not magically improve judgement. What it does is strip away the illusion.

‘Failure kills ego very quickly,’ he says. ‘You stop believing the story you tell yourself.’

After a collapse, priorities shift. Growth loses its shine if it comes without control. Revenue matters less than margin. Cashflow becomes something felt daily, not reviewed monthly.

A global study by the OECD into SME performance found that founders with prior business failures were more likely to implement tighter financial controls and stress-test assumptions in later ventures. Experience earned under pressure often translates into discipline.

‘You stop romanticising business,’ Haycox explains. ‘You start respecting it.’

Collapse versus defeat

One of the distinctions Haycox returns to often is the difference between failure and finality.

‘A business collapsing is an event,’ he says. ‘Defeat is a choice.’

He has watched founders respond to failure in very different ways. Some become defensive, blaming timing, partners or markets, only to repeat the same mistakes. Others take responsibility, reassess their assumptions and return with sharper judgement.

‘The second group is dangerous in the best way,’ Haycox says. ‘They’ve already lived through the worst-case scenario.’

That perspective shapes how he now evaluates people. A spotless track record does not always inspire confidence. Experience earned under pressure often counts for more than uninterrupted success.

Why avoiding failure weakens businesses

Haycox believes the cultural fear of failure creates fragile companies. Founders hide problems, delay difficult conversations and protect appearances instead of confronting reality.

‘If you can’t admit something’s wrong, you can’t fix it,’ he says.

Data from PwC’s Global Crisis Survey has shown that organisations which identify and address problems early recover faster and suffer less long-term damage than those that delay action. The same principle applies to small businesses.

‘Failure handled early is manageable,’ Haycox says. ‘Failure ignored becomes lethal.’

In environments where second chances are rare, leaders are incentivised to maintain the illusion of control. The result is slower reactions and larger collapses when issues eventually surface.

Separating identity from outcome

One of the most damaging aspects of failure, Haycox argues, is how closely founders tie their identity to their business.

‘When the company goes down, they feel like they’ve gone down with it,’ he says.

That emotional entanglement clouds judgement. Decisions become defensive. Risk is either avoided entirely or taken recklessly in an attempt to recover status.

Haycox learned, over time, to separate who he is from what he builds. ‘I am not my balance sheet,’ he says. ‘Once you understand that, you make better decisions.’

This mindset is something he frequently discusses in his long-form conversations, where themes of responsibility, resilience and rebuilding recur across industries and backgrounds.

Failure as a filter, not a verdict

Rather than seeing failure as disqualifying, Haycox views it as a filter. It reveals how individuals respond when momentum disappears.

‘Anyone can look capable when things are going well,’ he says. ‘Pressure shows you what’s underneath.’

That belief informs how he approaches business and media. He is less interested in flawless narratives and more focused on how people behave when certainty vanishes.

It is also why his commentary resonates with founders who feel alienated by constant success stories. Hearing failure discussed openly creates space for more honest conversations about risk and recovery.

A different message for entrepreneurs

Haycox is careful not to glorify struggle. His argument is not that failure should be chased, but that it should be expected.

‘The goal isn’t to fail,’ he says. ‘The goal is to build something real, knowing failure is possible.’

As markets tighten and competition intensifies, he believes this mindset will become even more important. Businesses built on denial are brittle. Those built with an acceptance of risk are more resilient.

That perspective runs through Haycox’s wider work, where he continues to challenge polished success narratives and focus on the realities founders actually face. More of his writing, interviews and long-form commentary can be found on his official website.

For entrepreneurs willing to confront the truth, his message is direct. Failure does not disqualify you. It tests you.

‘If you survive it and learn,’ Haycox says, ‘you don’t come back weaker. You come back informed.’

In entrepreneurship, that may be the most valuable edge of all.

Reducing Workflow Gaps in Marketing Campaigns With Virtual Assistants

Reducing Workflow Gaps in Marketing Campaigns With Virtual Assistants

Here’s a scenario you know too well: your marketing team never stops working, yet somehow deadlines slip past anyway. Creative assets get stuck waiting for someone’s approval. Follow-ups? They vanish into thin air. And when launches finally happen, half the tracking isn’t even set up properly. Sound familiar?

That’s the exhausting cycle of staying busy without actually moving forward. What you’re about to read shows you how marketing workflow optimization combined with virtual assistants for marketing can reduce workflow gaps, accelerate your execution, and maintain campaign quality all through systems you can roll out this week.

The Hidden Workflow Gaps Destroying Your Campaign Results

Before you can fix the problem, you need to see where it’s hiding. These gaps don’t send you warning emails or show up in Slack; they just quietly wreck your campaigns from the inside.

Want a jaw-dropping number? Marketing teams collectively hemorrhage somewhere between $75 billion and $1.6 trillion every year because of poor customer support , and a massive chunk of that traces back to operational failures. These aren’t the dramatic, everyone-panic-now failures either. They’re the quiet ones that chip away at every single campaign stage.

Where Campaigns Actually Break Down

Think about the moments when work changes hands. Planning for production. Production to approvals. Launch to monitoring. That’s where things fall apart. Briefs that never quite get specific enough. Assets that almost make the deadline. Tasks where nobody’s really sure who owns what. Then there’s the technical stuff UTM parameters that go missing, CRM records that never sync up creating reporting nightmares down the line.

Most teams only catch these problems after the damage is done. A launch gets pushed back a week. Tracking breaks halfway through the campaign. The frustrating part? These patterns keep repeating because nobody ever fixes the underlying system.

What These Gaps Actually Cost You

Missing a launch window means losing revenue you’ll never get back. When your ad creative sits stagnant, your audience tunes out. Respond to leads too slowly, and they’re already talking to your faster competitors. Quality takes a beating too, messaging that contradicts itself across platforms, tracking links that lead nowhere, reports full of garbage data. All of it starts with workflow gaps that seemed insignificant at first.

Building a Marketing Workflow System Around Virtual Support

Spotting the gaps is the easy part. The transformation comes when you build an operating system specifically designed to prevent them from forming.

This is where marketing virtual assistant services become game-changing. You get execution specialists who don’t just check boxes they maintain the operational discipline that keeps everything moving. These services handle recruitment, vetting, ongoing management, all the operational headaches you don’t want touching your plate.

Creating Your Campaign Operations Framework

Each campaign stage needs crystal-clear inputs and outputs. Your brief isn’t actually ready until it spells out the goal, audience, offer, channels, and how you’re measuring success. Assets can’t move to production until someone’s confirmed specs, brand alignment, and approval status. The RACI model (Responsible, Accountable, Consulted, Informed) kills that awkward “wait, weren’t you handling this?” moment cold.

This framework brings predictability into chaos. Everyone knows exactly what’s needed before handing work off. Fewer revision rounds. Fewer midnight fire drills.

Building Execution Pods That Streamline Marketing Campaigns

Here’s how you organize virtual support: create specialized pods. Your Content Pod runs editorial operations. Paid Media Pod traffics ads and manages creative variants. Lifecycle Pod owns everything email and CRM. Each pod has clear ownership and scales from a single virtual assistant up to multiple specialists as work volume demands.

Pod structure stops the inconsistencies that plague multi-channel campaigns. Someone’s always monitoring the critical workflows. Done right, virtual assistants for marketing become the connective tissue holding your entire campaign operation together.

How Virtual Assistants Actually Close These Workflow Gaps

You’ve got your framework and your pods defined. Now here’s where virtual assistants transform that blueprint into real improvements in speed, consistency, and follow-through.

Teams running virtual assistants for six months see engagement climb 45% and email conversions jump 30% . These aren’t feel-good vanity metrics. These are the results of systematically closing workflow gaps.

Moving Faster Without Breaking Things

Virtual assistants own repeatable execution and QA, which liberates your strategists to actually think strategically instead of drowning in operational minutiae. They maintain daily task queues and weekly sprint plans, establishing a rhythm you can rely on. Quality stays high because they’re executing documented processes, not making it up as they go.

Separating strategy from execution eliminates bottlenecks. Your team gains breathing room without hiring more full-timers or burning out the people you already have.

Never Missing Another Lead

Speed-to-lead determines whether prospects convert or ghost you. Virtual assistants handle inbox coverage, route inquiries based on your rules, enrich lead data, and keep your CRM current without lag. AI-powered virtual assistants now automate over 70% of customer queries, managing routine stuff while escalating anything complex.

When someone’s dedicated to monitoring and response, hitting your SLA targets becomes realistic. This consistency directly impacts revenue by capturing leads your competitors are too slow to catch.

Which Tasks Should You Actually Hand Off to Virtual Assistants?

Understanding benefits matters, but knowing precisely which tasks to delegate and when separates teams that thrive from teams still drowning in bottlenecks.

Not every task deserves your personal attention. Virtual assistant benefits show up when you offload high-volume, repeatable work that’s draining your internal capacity.

The Unglamorous Pre-Launch Work

Campaign calendars with dependency tracking. UTM builders with QA protocols. Landing page setup with form testing. Pixel and GA4 event checklist verification. Partner asset distribution. Follow-up coordination. Zero glamour, maximum impact. When these details slip through the cracks, campaigns launch broken.

Delegating this layer guarantees on-time launches with proper measurement locked in place.

Running Your Content Engine That Streamlines Marketing Campaigns

Editorial operations span brief creation, outline development, CMS uploads, internal linking, image optimization. Virtual assistants also manage repurposing workflows transforming blog posts into LinkedIn carousels, video scripts, newsletter content, sales enablement snippets.

This systematic approach prevents content droughts and squeezes maximum value from every piece across all your channels. Consistency improves. Publishing schedules hold. Teams stop scrambling for fresh material every week.

Your Questions About Marketing Virtual Assistants Answered

How do virtual assistants handle access securely without risking client data?

Professional virtual assistant services rely on password managers, role-based permissions, and secure VPNs. They follow data handling protocols aligned with GDPR and industry standards, keeping client information protected throughout every task.

How many hours weekly do I need to meaningfully reduce workflow gaps?

Most teams notice impact starting around 20 hours weekly for focused campaign support. Part-time coverage handles routine execution. Full-time virtual assistants manage end-to-end workflows across multiple channels while maintaining operational systems consistently.

Can virtual assistants run analytics, UTMs, and dashboards without breaking attribution?

Absolutely, once properly trained on your tech stack. Virtual assistants follow your documented tracking protocols, maintain UTM governance sheets, conduct QA checks, and update dashboards using your templates. This structured approach preserves measurement integrity while speeding up reporting.

Final Thoughts on Closing Workflow Gaps

Campaign delays don’t resolve themselves. Neither do handoff breakdowns or inconsistent execution. The teams winning right now? They’ve built systems documented processes, clear ownership, dedicated execution support through virtual assistants.

They’ve escaped the “everyone does everything” chaos and entered predictable, scalable operations. Your campaigns can operate the same way. Start by mapping one workflow gap. Document how to fix it. Delegate the execution. Speed and quality aren’t enemies when the right systems support both.

Move Fast Restoration Strengthens Emergency Response Services with Certified Water Extraction and Water Damage Cleanup Expertise Across Maryland

Water emergency property damage remains on the increase in both residential and commercial properties in Maryland. Leaks of appliances and burst pipes, along with storm floods and sewage overflow, are all reasons why timely and competent action is significant in eliminating the destruction. The IICRC and MHIC (Maryland home improvement contractors) certified Move Fast Restoration keeps growing its emergency restoration business by offering quick solutions that are supported by industry certification, modern equipment, and time-tested restoration techniques.

Move Fast Restoration is a reliable water damage cleanup experts that offers services to homes, apartments, offices, schools and commercial buildings in Baltimore and nearby places. The company aims at quick evaluation, accuracy in extracting water and full drying of structures in order to minimise secondary damage like mold, brittle structures and indoor air pollution issues.

The center of these services is a professionally trained workforce made up of certified water extraction professional staff who are capable of handling small-scale water leakages and those involving massive wastage of water. Every project is guided by industry guidelines as stipulated by IICRC so that the results of restoration are safe, effective, and consistent.

Professional Response to Water Damage Developed with Rapidity and Precision

Water propagates fast via the walls, floors, ceiling, and through the concealed spaces. In the absence of immediate action, water can cause severe structural issues and poor living conditions. Move Fast Restoration is an organization that operates under a 24-7 emergency response paradigm, and the technicians are able to arrive at the scene within a short period of time and commence the mitigation efforts immediately.

The process of restoration starts by conducting a complete inspection in order to detect both the obvious and concealed moisture. Moisture meters and thermal imaging are professional tools that are used in the search for trapped water on the surface. This solution enables the selective extraction and drying process and minimises the unwarranted disturbance of the property.

The team works with high-performing extraction systems to extract standing water. Technicians are IICRC certified water extraction experts and therefore use proper methods of extracting water, depending on the type of water, the surface and the contamination level. This is a systematic method of protecting flooring and walls, as well as individual property, and it hastens recovery time.

High Technology Drying and Dehumidification

Controlled drying is necessary after the elimination of the water. Move Fast Restoration employs commercial-grade air movers, as well as air dehumidifiers, which are safe to use and restore the normal moisture level in the office. Constant monitoring also makes sure that the process of drying is on track and materials are not overdried or not dry.

This elaborate process of drying helps in the long-term stability of the property and minimises the chances of microbial proliferation. Effective drying will also assist in controlling expensive repairs since as many materials as possible will be preserved.

In the process, records are kept to facilitate the insurance claims and ensure that the standards of the restoration have been achieved.

Reliable Water Damage Repair Company for Homes and Business Structures

Move Fast Restoration is one of the trusted water damage cleanup providers that operate in Baltimore and neighboring areas. Services are designed to meet a large variety of water damage scenarios, such as:

- Burst or frozen pipes

- Roof intrusion and storm invasion.

- Failure of appliances and plumbing.

- Sewage overflows and backups.

- Bases and crawl spaces flooded.

The response approach in each case will have to be different depending on the source of water and the level of contamination. During the restoration of damaged spaces, technicians adhere to the set safety protocols in order to ensure the safety of the interior spaces.

Residential services are aimed at securing living areas, furnishings, and indoor air conditions. Commercial services are used to reduce downtime and return the business operations to normal within the shortest period possible. Schools, offices and multi-unit properties enjoy the benefits of coordinated clean-up plans that restrict disruption as well as guarantee adherence to safety.

Water mitigation is a necessary measure to prevent molds.

Moisture can be left unsolved and will result in the growth of molds in under 24-48 hours. Proper water damage cleanup is an essential aspect of the prevention of the problem of the mold. Move Fast Restoration uses moisture control and sanitation measures in all projects to minimize the risks of mold.

In the case of mold, there are mold remediation services that are offered through procedures that integrate containment, air filtration and removal without unwarranted demolition. This will save structures and recover healthy indoor environments.

Water damage is a very serious problem with many long-term ramifications, but these can be prevented by prompt and comprehensive treatment.

Licensed, Certified, and Local Trust.

Move Fast Restoration is fully licensed and certified by MHIC (Maryland home improvement contractors) , which supports adherence to the standards of professionalism and safe restoration procedures. Technicians are constantly trained to keep up with the restoration practices, safety practices, and usage of equipment.

The service areas are located in Baltimore and neighbouring areas like Towson, Parkville, Catonsville, Dundalk, Essex, Owings Mills, Pikesville, Glen Burnie and Ellicott City. Local expertise enables quicker reaction time and guidelines for local building construction and risks associated with weather.

The local nature will enable the company to offer stability and reliable services in case of an emergency.

Insurance Claims and Property Recovery.

Incidents of water damage usually have insurance coordination. Move Fast Restoration helps in documentation, moisture measurements and damage reports to be used by insurance companies. Proper records contribute to simplifying the process of claims and contributing to a fair evaluation.

Restoration services facilitate the stabilisation of the property at a quick speed with strategising on the required repairs. In case a reconstruction is needed, there are coordinated rebuilding services that can be used to restore the affected areas safely and efficiently.

Resolution to Safe, Clean and Reliable Restoration.

All restoration projects are well organised with a purpose towards safety, cleanliness and lasting protection. The equipment is sufficiently maintained on a professional level and work areas are also well organised during the process of restoration.

Excellent communication and timely updates will make sure that the property owners and managers are updated at every stage of the cleanup and restoration. Emergency services will be available within 24 hours so that the cases of urgent water damage are solved immediately.

About Move Fast Restoration

Move Fast Restoration is a damage restoration company headquartered in Maryland, and it deals with water damage cleanup, mold remediation, and property restoration services. The company is renowned for responding quickly and with certified expertise to residential and commercial properties in the Baltimore region. Being safety-oriented, accurate, and reliable in results, Move Fast Restoration still offers professional solutions to the emergency of property damage.

Move Fast Restoration is available 24/7 throughout Baltimore at all times in case of an emergency and the provision of restoration aid.

Company details

Company Name: Move movefast Restoration

Contact Person: Ron Brandes

Email: Ronb@movefastrestoration.com

Phone: +1 410-650-5000

Address: 344 E. 25th 1/2 St. Zip Code 21218,

Baltimore, MD, United States

Website: https://movefastrestoration.com/